I wanted a place to store this great little article on Paiwari making and the science behind it. My appologies to the author for copying it without permission, but it is an obscure article and hard to locate. (The author may write me if he wants it removed.)/drf

The Science Behind Paiwari Making by

Indians

From

Earliest Recorded Use of Biotechnology Procedures in Guyana by Seelochan Beharry PhD. http://www.pantribalconfederacy.com/

and specifically, http://www.pantribalconfederacy.com/confederacy/News/pdf/Earliest_Recorded_Biotechnology.pdf

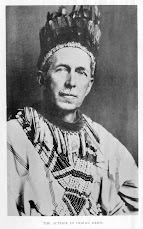

The late Sir Everard F. im Thurn

(MA. Oxon, b1852 - d1932) published (1883) a work entitled: “Among the Indians of Guiana: Being Sketches Chiefly

Anthropologic from the Interior of British Guiana.” I have in my

possession a copy of the Dover

Publications Inc, New York,

1967 (Library of congress #66-30384). This Dover edition first published in 1967 is an

unabridged and unaltered republication of the

work originally published by Kegan, Paul, and Trenton Co, 1883.

There are detailed descriptions of

how Cassava bread is made, with variations under different conditions when the cassava is scarce. However, we want to focus on the earliest recorded incidence of ‘Biotechnology’

procedures in British Guiana. (This is from my contemporary readings of our national

historical documentation – I am of course subject to correction by evidence to the contrary by the

experts in this field.)

On Page 263 of the abovementioned work (over a century ago), we

read: “Much cassava, after being made into bread, is further

transformed into paiwari, the chief Indian beverage. Astounding quantities of

this are consumed at special drinking bouts, of which we shall hear more

presently. But paiwari is

also largely used at other times;

and indeed as long as there is any

cassava to be had, a stock of this liquor is always kept ready. Whenever the men return from

hunting, and whenever a stranger comes

into the house, it is drunk. And women and children – even the

youngest babies – drink it.”

“Cassava bread which is to be

transformed into paiwari, is

made as that for other purposes; but

it is thicker, and is baked, or rather

burned, until it is quite black. It is then

broken into smaller fragments, and is mixed with water in a large jar or pot.

The larger fragments are picked out and chewed by the

women, who do this while moving

about and performing their usual

household work; and the masses are

again replaced in the jar. As soon

as this jar is sufficiently filled, its contents, after being well stirred, are

slightly boiled, and are then poured

into the trough. More and more is

added to the liquor in the trough. More and more is added to the liquor in the

trough until it is full.”

“The mixture is then allowed to stand for some

days, until it is sufficiently fermented – a process which is said to be much

accelerated by the mastication of the bread. Sometimes

a little juice of sugarcane is added to sweeten the

liquor. The result is a brownish liquor –looking like coffee with a great deal

of milk in it - with a sub-acid, but not unpleasant taste. Some of the

True Caribs, it is said, and some of

the Brazilian tribes, manage to prepare

paiwari, and to procure a proper

degree of fermentation, by simply boiling, without resorting to the very disagreeable but more orthodox chewing

process; but paiwari produced in this way is said to be of very inferior

flavour.”

“In some

parts of the country, instead of paiwari, both for festivals and for

ordinary occasions, a much pleasanter drink is used. This is casiri, which is made of sweetpotatoes

and sugar-cane. A little cassava is sometimes

added. Generally, though not always, it is prepared simply by boiling the ingredients, and allowing them

to ferment. It has a pretty pink colour, due to the

sweet potatoes; and when well made it tastes not unlike thin claret. ……”

For those who love to eat and have

done some science, we would remember

that digestion of food begins in the

mouth – i.e. chewing breaks down the

size of the food particles to

smaller and smaller-sized ones. This chewing is necessary so that we can have the maximum surface area of the

food exposed to the saliva – produced

by the salivary glands in the mouth. This chewing therefore

also maximises the efficiency of the catalytic process that occurs in the presence of saliva. The saliva produced in the mouth contains an enzyme called human salivary

amylase also called ptyalin (among other

chemicals) which is mainly called alpha amylase that breaks down a complex carbohydrate such as starch (polymer of

glucose) into simple sugars (monosaccharide, disaccharide or trisaccharide e.g.

such as glucose, maltose, maltotriose, respectively, and “limited dextrin”). The

alpha amylase enzyme is present in very small amounts in the

saliva. Usually, in any biological enzymatic process only a small amount of the catalyst is needed. The alpha amylase enzyme

(like other enzymes) here works best

at a particular pH (i.e. a measure of acidity or alkalinity) range (in this

case slightly alkaline, 7.4). (Incidentally, the

saliva also contains another enzyme

called lysozyme that lyses (breaks down) bacteria, in addition to other anti-bacterial compounds.)

This saliva helps to sterilise any

bacteria that would remain on any improperly washed or handled cassava. Hence the saliva destroys any bacteria present as well as

breaking down starch to form glucose, maltose, maltotriose and “limited

dextrin”- done by alpha amylase and lysozyme, respectively.

The stirring mentioned above also

allows for maximum exposure to the

enzymatic processes – thereby

maximising the efficiency of the catalytic breakdown of starch into maltose. The

heating to a slight boiling denatures (kills) the

enzymes - thereby stopping the catalytic action of the

enzyme (alpha amylase). This phase of the

production process is over. The heating to a boiling also acts as sterilization

step – since heat kills bacteria, viruses, and other

living micro-organisms that may also be present.

The sterilised maltose is now ready

for the next step - fermentation of

simple sugar i.e. maltose into alcohol. (Incidentally, from

cane sugar we extract the sucrose (a

disaccharide) which is then

fermented to give alcohol.). Unfortunately, I found no detailed record of how the fermentation process was/is initiated,

controlled, and stopped. Maybe those with this knowledge or experience can

kindly let us know.

We see from

the above that the old making of paiwari is indeed complex

science - and the participants

involved intuitively must have some

understanding of the biological chemistry

or biochemistry involved. Today such a complex

process would be in the realm of

applied science i.e. biotechnology, since it involved the

use of biological materials in a complex

production process.

Next time, we see Amerindians I hope

that we have more respect for their

immense knowledge. If we look carefully without prejudice, we can learn a lot

from them.

They do have a lot to teach us – we just have to be open-minded.

I taught biochemistry at UG,

regrettably I was not aware at time that there

was a good local example of the

application of early biotechnology in Guyana. I never learnt about this

until I was doing some research about

the ‘Rupununi Uprising.’ Who knows what other

gems are there to be discovered and

record before they are lost.

These liqueurs (paiwari and casiri) can probably be produced for commercial exploitation using alpha-amylase. Besides the use sweet potatoes in casiri, fruits such as ‘jamoon,’ goose-berry, tamarind,

and/or other local fruits can be

used to make flavoured liqueurs. This would provide an additional market for

cassava–based products. This would be a good enterprise for DDL or some adventurous group of young entrepreneurs.

Hope that next time we can all

celebrate Amerindian Heritage month with a new found respect for their contribution and knowledge – in addition to their knowledge in forestry, botany, zoology, and their environmental awareness.

Seelochan Beharry PhD.

also another

article

No comments:

Post a Comment