In the

process of acquiring a couple of Everyland magazines with articles by the author Verrill, I noticed this magazine in the vendor’s virtual storefront. I thought it might

be interesting so…/drf

The Story of Aluminum

From the

magazine, Industrial Arts and

Vocational Education March,

1931. Digitized by Doug Frizzle, June 2012.

From the

magazine, Industrial Arts and

Vocational Education March,

1931. Digitized by Doug Frizzle, June 2012.

READ IT TO YOUR STUDENTS —Inspirational

—Tells How a Typical American Boy Achieved Fame and Riches.

“PROFESSOR—I've got it!" exclaimed a

young man, bursting excitedly into the

private laboratory of the head of the chemistry department of an Ohio college, on the

morning of February 23, 1886.

Extending his cupped hand, he

proudly exhibited to the astonished

professor, half a dozen little globules of a silver-colored metal.

It was no wonder he was

excited, or that his excitement was shared by the

incredulous professor, for at 22 years of age he had achieved what some of the

world's greatest scientists had failed to achieve after half a century of

application to the same problem. And

where they had enjoyed the facilities of great laboratories, with all

manner of scientific equipment, and yet had failed, this 22-year-old American

youth had worked out the problem in the woodshed in his backyard, with the crudest kind of equipment.

IT all came about as the result of a chance remark made by Frank Fanning

Jewett, his chemistry professor at Oberlin

College, one morning

during the young man's senior year.

In talking with the students in his

chemistry class Prof. Jewett made the

offhand observation that if anyone should invent a process by which aluminum

could be made on a commercial scale,

he would not only be a benefactor to the

world, but he would also be able to lay up for himself a great fortune.

Serious-minded Charles Martin

Hall nudged a classmate and whispered, "I'm going for that metal."

Go for it he did, and in dead

earnest. Discovering a cheap method of producing aluminum became an obsession

with him. Had he known that he was racing with another

young man, across the seas, and had

he realized how nearly the two would

tie each other, he would scarcely

have slept during the next year! As

it was, he spent much of his spare time outside of school hours in the college laboratory working doggedly on the problem, for he had read somewhere,

that every clay bank was potentially a mine of aluminum, and that the metal was as costly as silver.

But all his application, and

all his admitted genius, and all his knowledge of chemistry, seemed of no avail

against this aluminum riddle. "Going for it" was one thing, but

getting it was quite another. All

avenues seemed to lead to failure.

It was not until eight months

after he had finished college that he started thinking along an entirely new

line. If aluminum could not be extracted inexpensively by the chemical processes with which scientists had

been struggling for half a century, and with which he had worked unsuccessfully

for so many months, might it not be done by electricity?

That was a new idea. It seemed

worth investigating.

Hall knew something of electrolysis and he lost no time in fitting up the

woodshed behind his father's house

on East College Street,

Oberlin, as a laboratory. Borrowing an odd assortment of battery jars and

plates from the

college laboratory, and buying a small crucible, he set them

along the edge of the upper floor of the

two-story woodshed, so that he could stand while at work, on the lower steps and oversee both levels. Then he set

up a homemade furnace and bellows.

Days were spent—precious days

that were worth hundreds of thousands of dollars to him had he known it—in

constructing crude pieces of apparatus that he had not the

small means to purchase.

At last, however, everything

was ready for an entirely new experiment.

Melting some cryolite in his little clay crucible, and

dissolving some "alumina"

(refined aluminum ore) in it, he switched on his batteries and passed the electric current through the

molten mass for about two hours.

We can imagine "with

what impatience he paced up and down in the

woodshed during those two hours!

Finally the time was up and he poured out the molten mass. Alas! There was no aluminum!

However, he was not

discouraged. Indeed, it is said of Charles Martin Hall that he was never

discouraged for more than a few hours at a time.

He started to think his way

into the problem, and it may be

observed in passing that Hall never worked at random

nor never stumbled onto things— he thought things through. In this instance, he

came to the conclusion that there might be some

impurities in his clay crucible and they

might be affecting the result.

Promptly

he constructed a carbon lining for the

crucible and he proceeded to repeat the

experiment.

Again he waited impatiently

for two hours as the current from his makeshift batteries passed through the molten mass.

Could he believe his eyes?

There, in the bottom of the

crucible, were a number of small globules of aluminum!

Excitedly he called his

sisters and showed them the still hot little "buttons" of

aluminum. (Some of these are today carefully preserved in the Pittsburgh

offices of Aluminum Company of America.)

As soon as these globules, or "buttons," were cool

enough to handle, Hall took them in the palm of his hand and hurried to the college, where he burst in upon Professor Jewett

with the startling news with which

this story opens "Professor—I've got it!"

That day—February 23, 1886—marked

the birth of a new metal age— The Age

of Aluminum!

Two months later to the day (April 23, 1886) a French chemist, Paul L.

T. Heroult (by coincidence also 22 years of age) applied for a French patent on

the identical process!

Hall had won by a margin of

eight weeks!

A New Industry Is Born

CURIOUSLY enough, after a company had been organized to produce aluminum by

Hall's process, one of the first

articles made was a teakettle. But this was not chance. Because it was known

that aluminum conducted heat so efficiently, and because it was so easy to keep

clean and bright, and because it promised

to wear forever, Hall and his backers saw that it was an ideal metal for

cooking utensils. Thus it was that aluminum got its first big start in the kitchen.

Everybody knows how aluminum

cooking utensils took America

by storm, and how much they have

lightened the drudgery of housework

and added to the cleanliness and

cheerfulness of our kitchens and the

wholesomeness of our meals.

But the

usefulness of aluminum was not to be confined to the

kitchen. It was destined to invade hundreds of industries and to be used for

thousands of purposes.

For example, because of its

light weight and excellent electrical conductivity, it began to be used to make

cable (with a core of steel wire for greater strength) for conveying electrical

current across country. Thousands of miles of aluminum power lines are to be seen

today.

When the

automobile came along a dozen new

uses were found for this light metal which automotive

engineers found saved weight and made possible speedier cars. Pistons and

connecting rods of aluminum alloys became almost standard in automobile engineering practice. Today, eight out of

ten motor car manufacturers use aluminum alloy pistons in their motors.

Close on the heels of the

automobile came the airplane, and here aluminum figured from the

first as an essential metal. It is the

cheapest metal that is light, and at the

same time strong enough to stand the

stresses and strains of air navigation.

However, these modern miracles of metallurgy were not accomplished with the

quality of aluminum which Hall had made in his woodshed laboratory. When

aluminum began to be used for industrial purposes, it was found that for some uses it lacked the

necessary strength. A research laboratory was established and presently, by combining aluminum with small percentages of other metals, a series of "alloys" was

developed. After these alloys had

been heat treated they became

exceedingly tough and strong —some

of them as strong as structural

steel.

These alloys contain 95 per

cent or more of aluminum, so they

preserve all the characteristic

lightness and bright color of the

parent metal, but they are many

times as strong and are now used for the

heaviest kind of duty. For example, the

bodies of some of the armored motor cars seen on our city streets, are

made of strong aluminum alloys. Could any but a stout metal be used for such a

purpose?

These alloys contain 95 per

cent or more of aluminum, so they

preserve all the characteristic

lightness and bright color of the

parent metal, but they are many

times as strong and are now used for the

heaviest kind of duty. For example, the

bodies of some of the armored motor cars seen on our city streets, are

made of strong aluminum alloys. Could any but a stout metal be used for such a

purpose?

When railroad and street car

companies began to face the necessity of lighter cars and locomotives, so that their

trains and trolleys might run on faster schedules to meet the demand for greater speed in transportation, they turned naturally to these

strong alloys of aluminum. Roofs, frames and side walls of passenger cars made

of rolled sheets and structural shapes of strong aluminum alloys. Drop-forged

aluminum driving-rods for connecting the

huge driving-wheels of powerful steam locomotives

are already beginning to be used, and the

time seems not far distant when aluminum will play a big part in speeding up our

train and trolley service all over the

country, at the same time reducing

operating costs for the

transportation companies.

From

year to year, many other interesting

discoveries were made about aluminum. It was found that this bright metal could

be ground to a flaky powder and made into paint. At first this flaky powder was

mixed with banana oil and used almost exclusively for painting radiators.

But soon paint makers found

that it could be mixed with varnish, like any other

paint pigment. When this aluminum paint is applied, the

minute flakes of metal overlap one another

(as revealed by microscopic examination), and form a tough and flexible

metallic coat that defies rain, sun, snow or hail.

This was an important

discovery, for while people may not want aluminum-colored houses, it has been

demonstrated that aluminum paint as a priming coat forms a thin film of metal

that protects the wood underneath

against moisture changes, and makes the

color coats that are put on top wear much longer. Eventually, it is thought, the best grades of lumber may come already "primed" with aluminum paint.

Another

interesting discovery was that aluminum could be rolled into foil—some of it so thin that it would take ten sheets to

equal the thickness of the paper on which this story is printed!

Because this foil is pure and

clean and will not tarnish, and because it is impervious to light or moisture

or gases, the manufacturers of food

and drug products soon discovered it to be ideal for wrapping their products. Foods may be kept in contact with it

indefinitely with perfect safety.

Today aluminum foil is used

for wrapping and protecting a wide variety of products—chocolate bars, candy

mints, chewing gum, yeast cakes, cheese, tea, film rolls, soap, cigars and cigarettes,

to mention a few.

Aluminum is also used for

screw caps for jars of vanishing cream, bottles of lotions, and many food and

drug products. Aluminum caps (often in color and bearing printed trademarks or

designs) are used for sealing bottles of ketchup, pickles, salad dressing,

etc., and for capping bottles of proprietary remedies.

Perhaps more interesting

still, soft aluminum is made into collapsible tubes for tooth paste, shaving

cream and numerous pharmaceutical products.

How little did Charles Martin

Hall dream what a contribution he was making to the

comfort of life on that February

morning when he rushed out of his woodshed laboratory with a few globules of

aluminum in his hand and started for Prof. Jewett's laboratory to break the news of his success!

And the

end is not yet.

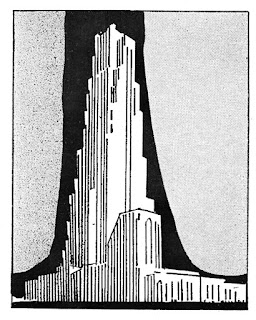

As the

skyscrapers in our great cities have pushed their

towers higher and higher, the

problem of weight has become more

and more important. Much metal is used for decorative purposes— for cornices,

spandrels, window frames, leaders and gutters, and the

like. This has opened up a whole new field for this metal that is only

one-third as heavy as the older

structural metals, will not rust, tarnish or discolor, and can be rolled or

cast or worked into any desired form.

Many modern offices are

furnished with aluminum chairs, either

left in their natural bright finish

or finished to resemble mahogany or walnut. And in many hospitals and

sanitariums and railroad dining cars, aluminum chairs are used because they can be lifted so easily and they will stand all sorts of abuse. Col. Lindbergh's

"flying office" is equipped with aluminum furniture.

Almost every month now a new

use is found for aluminum in some of

its forms or alloys. The business that started in an Oberlin, Ohio,

woodshed now spreads out over the

map of America from Niagara Falls to Bauxite, Arkansas;

and from Edgewater,

New Jersey, to Oakland, California.

In addition to mines, it operates great ore reduction plants, power plants,

foundries, rolling mills, tube mills, wire mills, and a variety of fabricating

plants, employing nearly 25,000 men and women.

And the

Aluminum Age is only in its dawn stage!

All this 'is amazing, when

you stop to think that, until Charles Martin Hall discovered how to produce

aluminum electrolytically in 1886, this metal which now plays so large a part

in our lives, was so expensive that it was regarded almost as a semi-precious

metal! Indeed, within the memory of

some who will read this story, aluminum

sold for $25.00 a pound, whereas it now sells for less than 25 cents a pound,

thanks to this Oberlin, Ohio, school-boy—and to the

activities of the scientists and

engineers of Aluminum Company of

America. Imagine being able to buy a $25.00 rug or a $25.00 chair for less than

25 cents!

Of course, Hall's original

process has been greatly improved, in the

forty-odd years that the research

engineers of the aluminum industry

have been working on this almost magical metal. Hall himself would be amazed at

some of the

properties of the aluminum that is

now being made, and at the enormous

plants producing great aluminum castings and beams and forgings, side by side

with airplane propellers, automobile

parts, paint pigment, aluminum cable, and tissue-thin foil.

You are probably curious to

know whether Hall realized a fortune

from his discovery. So few inventors

do.

Well, Hall did. When he died

in 1914, he was the largest

stockholder in the Company and left an estate worth several millions.

And the fine thing about it was that

he left his stock in the Company to educational and philanthropic causes.

One-half was left to Oberlin and another

American college, one-sixth to education in the

near east and the remainder to

philanthropic organizations.

But his greatest legacy was

an industry which serves us all, making our work easier and our lives more

cheerful and comfortable.

Aluminum Company of America is not the only factor in this fast-growing American

industry. It is the largest single

factor, and the sole producer of the virgin metal in this country. But there are a number of other

important companies making aluminum

castings, sheet aluminum for fabrication purposes, and aluminum products of

many kinds. Furthermore,

considerable foreign-made aluminum is imported.

In order to establish the identity of its own brands, and to build

good-will around its name, Aluminum Company

of America

has created a trade name. That name is made up of three syllables, AL CO A,

standing for the beginning letters

of the principal words of its name:

ALuminum COmpany of America.

ALCOA ALUMINUM is the highest standard in the

world.

To all modern developments

aluminum is making an important contribution. To some

it is absolutely essential. That is why, as we face the

future in America,

we find ourselves only just crossing the

threshold of this wonderful new age—The Aluminum Age!

ALUMINUM COMPANY of AMERICA;

Oliver Bldg. Pittsburgh, PA.

No comments:

Post a Comment